You must be signed in to read the rest of this article.

Registration on CDEWorld is free. You may also login to CDEWorld with your DentalAegis.com account.

The use of computer-assisted design and computer-assisted manufacturing (CAD/CAM) technology began in the mid 1940s for industrial and engineering applications in design.1 Dental applications of CAD/CAM have been available for almost 30 years, and a considerable amount of in-vitro and in-vivo research has been published documenting the clinical efficacy and longevity of restorations fabricated from CAD/CAM.2-4 This article will review some of the recent trends and innovations in CAD/CAM equipment in dentistry along with current and future clinical applications. It will discuss the integration of digital technology into dental practice and dental laboratory settings. Intraoral digital scanning and lab scanners will be reviewed along with the multiple options available regarding the uses of such optical impression data.

CAD/CAM in Dentistry

Recent growth trends of CAD/CAM systems for industrial applications in rapid prototyping have facilitated significant improvement in software and a reduction of size and costs of machinery. Such trends have allowed for CAD/CAM to be adopted into numerous other fields, including medical and dental applications. CAD/CAM in dentistry has been particularly useful in permitting the fabrication of custom, patient-specific restorations and prosthetics without having to use traditional analog dental laboratory methods.5

The general workflow for adoption of CAD/CAM has been well documented and typically begins with acquisition of either intraoral data using a chairside intraoral scanner or a model-based scan using larger laboratory-based scanners. The digital data acquired is processed into a computer program that builds the geometric data that is transferred into a modeling algorithm.1,6 Generally, computer design software is used to analyze and alter the acquired data. In addition to visualizing the data in 3-dimension (3-D), dental-specific CAD software enables limitless design of restorations in an open software environment rich with digital design tools similar to analog tools used in a dental laboratory.

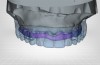

Various dental CAD software exists, and each has a different capacity and dental application. CAD applications range from analysis tools for orthodontics and oral surgery to restorative design tools for crowns, onlays, inlays, veneers, copings, frameworks, removable prosthodontic appliances, orthodontic appliances, implant prosthetics including abutments and crowns, splints, surgical guides, and more (Figure 1 and Figure 2). The software allows for complete design of the specific dental application and includes the ability to freely configure, construct, shape, size, and adapt the designs to the original surface data scanned. Often, the objective is to produce the restoration through the CAM process of either milling or constructing through additive rapid prototyping.1 The process of manufacturing ranges from convenient chairside milling units to sophisticated laboratory-based mills for complex multi-axis machining and fabrication.

There are multiple successful workflows for digital dentistry.7 Some are closed loop systems that create a seamless operating environment, but may not have flexibility or compatibility for cross-system integration. Other systems are designed with open architecture for freedom of design and machining. Such open systems require great care, diligence, and quality control analysis from the operator to control the grade of the final product.1 Often, dental acquisition units for CAD and dental milling units for CAM are bundled together by manufacturers to limit the variables that often demand a thorough understanding of CAD/CAM engineering. Common items to be considered when evaluating dental CAD/CAM systems include the manufacturer/brand, CAD hardware, CAM hardware, software, and system functions and capabilities. Because every system is different in regards to hardware and has different dental applications, the end-user should thoroughly evaluate each system and its dental-specific applications.

The CAM process resultant should be evaluated with the same quality control and inspection as when using traditional methods.8 The digital workflow of CAD/CAM typically offers higher accuracy and efficiency than traditional methods used in the dental laboratory but still requires a thorough understanding of CAD/CAM calibration and parameters for the product to be clinically acceptable.9 Usually, clinicians and technicians alike require time and repetition to perfect the result of the digital process. Once understood, CAD/CAM dentistry can create restorations that function and perform with great success and longevity.

Digital CAD/CAM Systems

There are two categories of commercially available digital systems for chairside dentistry: digital impression systems and comprehensive chairside CAD/CAM systems with simple clinician-friendly software. For dental laboratories, CAD/CAM systems include a vast array of scanners, milling, and rapid prototyping units. The software available to the dental laboratory industry tends to be more robust and sophisticated, allowing for complete customization and control of acquisition, design, and milling. Although the laboratory software is more stout, the rich features and software workflow are not conducive to chairside application.

All of these systems build on a basic CAD/CAM workflow of digital acquisition of data (via either direct intraoral scan or a model scan). Digital impressioning systems are designed to streamline and replace traditional analog oral impressions of a patient’s intraoral condition (either preoperative condition for diagnostic models, or final impressions for prosthetic construction). The data acquired can be evaluated and analyzed chairside and must be transmitted electronically to the laboratory for use in multiple applications, including model fabrication, prosthetic design, orthodontic design, and restoration fabrication. The objective of digital impression systems is to accurately record the intraoral condition to a CAD data file that can be manipulated only by the laboratory or manufacturer.10,11 The lab has the ability to convert a digital impression into an analog model through either milling or rapid prototyping such as stereolithography (SLA).12 Once the model is generated, the lab can either initiate a traditional workflow for restoration fabrication or simply use the model as a reference and for fit evaluation of the final CAD/CAM restoration.7,13 Alternatively, comprehensive chairside CAD/CAM systems provide all stages of digital dentistry and deliver the ability to acquire digital data, analyze and design, and, finally, fabricate prosthetics using milling technology.

The development of CAD/CAM for clinical dentistry was initially established for single-tooth fabrication of indirect restorations.14 Initially, these CAD/CAM systems were designed to handle single restorations such as inlays, onlays, crowns, and veneers (Figure 3 and Figure 4).2 Today, both chairside and laboratory-based CAD/CAM systems have evolved to provide a broader scope of clinical applications and products for dentistry.

All CAD/CAM systems require some method of data input for capture of intraoral conditions into the CAD software. Most systems have adopted a digital intraoral camera or scanner for image acquisition; in particular, all chairside systems incorporate an intraoral camera.15 Most chairside CAD/CAM systems claim intraoral scanning for image acquisition, but due to certain limitations in design and scanning requirements, some intraoral camera systems are used to scan stone master models produced by the clinician. Although manufacturers have modified the software to recognize stone-model–based scans, the data is often less accurate than direct intraoral scans due to known distortion in traditional impressions and setting expansion of dental stone.16,17

The digital data acquired by an intraoral camera or scanner eliminates the need for traditional impressions and bite registrations. The digital nature of chairside CAD/CAM systems changes the clinical workflow of traditional restorative dentistry. Modern CAD/CAM systems expedite the clinical appointment and improve workflow efficiency (Figure 5 through Figure 7).7 In the past, initial intraoral scanners that were available when CAD/CAM was first introduced to clinical dentistry obtained digital data by producing static images of prepared tooth structures and stitched these static single images into a larger virtual model.4 Initial scanners were often limited by the software algorithms and computer microprocessor speeds inside the acquisition unit. Due to limitations in computer processing, early versions of CAD/CAM systems were not capable of acquiring large digital models and were often limited to the quadrant of the patient arch being treated. Modern computers with updated central processing units (CPUs) and graphical processing units (GPUs) are capable of handling much more data. Advances in both CPUs and GPUs have allowed for advancements in intraoral scanning hardware and CAD/CAM software, thus improving both scanning speed and size. With the ability to capture full-arch scans, the dental applications for CAD/CAM are no longer limited to single-tooth restorations.18

In addition to advances in computer hardware, manufacturers of CAD/CAM systems have focused on developing intraoral cameras that are more ergonomic with smaller, patient-friendly designs. While earlier versions of intraoral camera systems were large and obtrusive in design, newer systems include cameras that fit comfortably intraorally, are less bulky, and provide improved intraoral access. Concerted efforts have been made on improving ergonomics for the clinician. The motions necessary to position, translate, and rotate the camera intraorally during image acquisition are extremely important and play a significant role in capturing accurate intraoral scan data.19 As with many dental procedures, an improvement in efficiency of scanning provides a better patient experience. Most recently, the introduction of portability to intraoral scanning systems has allowed clinicians “plug-and-play” ability. They can simply use the camera to obtain digital data for the CAD software that is retained on a central server, using an existing computer and network infrastructure. These plug-and-play style cameras alleviate the need for the traditional cart-based system that houses the CPU, viewing monitor, CAD software, and digital intraoral scanner.

Chairside impression and CAD/CAM systems can be further divided by software architecture as either open or closed architecture systems. Open architecture refers to the format of the data that is acquired as being compatible across multiple, different manufacturers of both software and hardware. An open system allows for transfer of data across multiple devices for design and final restoration. Driven by manufacturer compatibility, open architecture CAD/CAM systems are becoming increasingly popular for laboratory-based systems. Closed architecture systems are common among chairside solutions primarily to help streamline the workflow. A closed architecture system precludes the exporting or importing of data into a different manufacturer’s digital system and requires the use of the system manufacturer’s hardware and software for imaging, design, and milling of the dental restoration. Benefits to such a system include a streamlined workflow that is controlled and consistent in quality.

Clinical Applications

Today, digital impression systems are designed to replace the traditional analog method of recording a patient’s intraoral condition through impression-taking. These digital chairside impression systems include both the hardware for scanning and the software for management of patient data. Although the learning curves for the various systems available differ, generally the use of an intraoral scanner requires an understanding of the specific imaging modality of the individual scanner (static images versus video streaming) utilized along with proper patient isolation and retraction.7 The software not only captures and stores the digital data from the intraoral scan, but also records standard information regarding patient vitals and replaces the traditional written laboratory prescription by including a comprehensive electronic prescription form. The data is archived within the computer system attached to the digital impression system and can be transmitted digitally to the lab via the Internet. Once the data is transmitted, the lab may open the data for evaluation, design, and production of the dental restoration. The digital impression system does not allow for the clinician to design or mill, as these features are only available to the lab that receives the digital scan data.

The chairside CAD/CAM systems provide the same intraoral camera or scanner and are capable of both designing and milling within the chairside workflow. Due to the comprehensive workflow of CAD/CAM systems, the clinical integration of such systems requires proper training and education. Typically, the learning curve for the comprehensive chairside CAD/CAM system is longer than that of the digital impression system. Specifically, the design function of the software for restoration design takes time to master.19,20 Furthermore, proper laboratory education is prudent for the finishing of the milled restoration prior to intraoral placement. Some CAD/CAM systems provide flexibility for the end-user by permitting the clinician to use only the digital impression portion of the system and then provide the data to a registered lab. When facing such clinical treatment challenges as limited restorative space or limitations in restorative material, the clinician may switch from a chairside workflow and send the optical impression to the lab for restoration fabrication. This feature creates flexibility for both the clinician and the patient alike depending on the clinical circumstances and restorative requirements.

According to recent studies, modern digital impression systems and chairside CAD/CAM systems have the capacity to provide accurate dental restorations in comparison to traditional laboratory-fabricated restorations.21-24 According to Fasbinder et al, there is evidence that digital systems can be more accurate than conventional master impressions and dental stone models.8 Like any dental instrument, both the digital impression system and chairside CAD/CAM system require proper setup, consistent intraoral protocols, and calibration of milling parameters to ensure exceptional clinical results.20

Restorative applications of modern CAD/CAM systems have improved in efficiency and accuracy of design and fabrication of traditional single-tooth restorations such as inlays, onlays, crowns, and veneers. As improvements have been made in material science, these digital systems have introduced chairside multi-unit restorations such as bridges, implant abutments and restorations, temporary restorations, and surgical guide fabrication. CAD/CAM removable prosthetics such as partial denture frameworks, partial dentures, and complete removable dentures are also replacing traditional analog methods of fabrication, though they require the use of laboratory-based CAD/CAM systems.

With advances in camera systems, scanners, and the ability to image full arches, orthodontic applications of CAD/CAM dentistry have expanded significantly. Intraoral imaging systems today allow for digital scanning of intraoral conditions prior to definitive treatment to create digital models. These digital models are processed in dedicated orthodontic CAD software to assist in diagnostic modeling for documentation, clinical diagnosis, and treatment planning with virtualization of tooth setups. More sophisticated laboratory-based CAD/CAM systems are available to create models through both milled and rapid prototyping methods. In addition, the lab-based systems allow for fabrication of patient-specific orthodontic brackets, custom robotically bent treatment wires, milled custom seating trays for bracket placement, clear orthodontic aligners and retainers, and fabrication of removable orthodontic appliances. When combined with 3-D cone-beam computed tomography (CBCT) imaging, the CAD data aids substantially in complex planning of orthognathic treatment and surgical approaches to orthodontic and airway therapy. While the clinical applications are quite evident, patient education is another major benefit to orthodontic CAD/CAM applications.

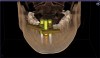

CAD/CAM systems have significantly improved comprehensive implant therapy.25 Recent developments in 3-D imaging for dentistry have paved the way for CAD x-ray software to aid in implant treatment planning and guided implant surgery. CBCT generates 3-dimensional digital radiography without the traditional distortion and magnification of traditional x-ray imaging modalities (Figure 8). Such 3-D imaging has become a preferred aid for accurate diagnostic measurements, comprehensive pathology diagnosis, and digital surgical treatment planning. When combined with implant software, the CBCT data can work with CAD data from digital impressioning systems to aid in restorative implant planning and placement. Essentially, the design software within the CAD systems can virtually wax-up teeth based on a functionally esthetic stable position and export the virtual restoration into a CBCT software environment to aid in ideal implant positioning (Figure 9 through Figure 11). Once the restoratively driven virtual implant position is complete, the data can then be utilized within the CAD/CAM system to fabricate a surgical guide for guided surgical implant placement (Figure 12 and Figure 13). Both chairside and laboratory workflows for surgical guide fabrication exist today and have improved the accuracy as well as reduced the morbidity of implant therapy.

In addition to surgical CAD/CAM solutions for dental implantology, restorative applications have expanded into implant fixture-level digital impressioning, design and milling of custom healing abutments, custom prosthetic abutments, single-tooth and multiple-tooth implant-retained restorations, frameworks, bar substructures, and telescopic implant prosthetics. Many laboratories have transitioned to CAD/CAM implant solutions with the traditional analog clinical impressions and models provided by the dentist. Laboratory-based benchtop scanners vary in style from small scanners for simple impression, die, and model scanning, to large scanners that permit scanning of fully articulated models. Major benefits of implant applications of CAD/CAM dentistry include improved accuracy and increased fabrication efficiency.

Improvements in dental material science have created an opportunity for CAD/CAM dentistry to replace traditional methods of restoration fabrication.26 Significant advancements have been made in CAD/CAM material esthetics, chemistry and strength, and biocompatibility for clinical dentistry. Highly esthetic glass ceramic materials can be used chairside for fabrication of single-tooth restorations that can be adhesively bonded. Some materials require post-mill processing such as firing in a ceramic oven to convert the material from a softer millable state to the final chemical state as an indirect restoration (as shown in Figure 5 through Figure 7). Although the chairside materials can also be fabricated with laboratory CAD/CAM systems, materials such as zirconium oxide, commercially pure titanium, titanium alloy, noble metals and alloys, composite resins, wax, and fiber-reinforced acrylics are primarily the mainstay of laboratory-processed restorations. These materials often require different milling protocols and post-processing for final finishing. Laboratory-based CAD/CAM materials are supplied in a form where multiple restorations can be milled within one large blank of material to reduce material waste and costs. An example of a laboratory workflow for a full-arch telescopic fixed implant prosthesis using CAD/CAM is depicted in Figure 14 through Figure 21. Ultimately, significant advances in both CAD/CAM technology and material science are paving the future for applications of digital dentistry.27

Conclusion

Digital systems for CAD/CAM dentistry have been improving as a result of innovation. Such innovation has also enhanced the clinical workflow and final clinical outcomes for patient therapy in restorative, surgical, and orthodontic care. As CAD/CAM systems continue to evolve, the research and clinical evidence of the effectiveness of CAD/CAM dentistry will help shape the future of all clinical dentistry.

About the Author

Neal Patel, DDS

Private Practice

Powell, Ohio

Queries to the author regarding this course may be submitted to authorqueries@aegiscomm.com.

Reference

1. Lalit Narayan K, Mallikarjuna Rao K, Sarcar M. Computer Aided Design and Manufacturing. New Delhi, India: Prentice Hall of India; 2008.

2. Fasbinder DJ. Clinical performance of chairside CAD/CAM restorations. J Am Dent Assoc. 2006;137 suppl:22S-31S.

3. Reiss B. Clinical results of Cerec inlays in a dental practice over a period of 18 years. Int J Comput Dent. 2006;9(1):11-22.

4. Mörmann WH. The evolution of the CEREC system. J Am Dent Assoc. 2006;137 suppl:7S-13S.

5. Fasbinder D. Using digital technology to enhance restorative dentistry. Compend Contin Educ Dent. 2012;33(9):666-672.

6. Beuer F, Schweiger J, Edelhoff D. Digital dentistry: an overview of recent developments for CAD/CAM generated restorations. Br Dent J. 2008;204(9):505-511.

7. Seelbach P, Brueckel C, Wöstmann B. Accuracy of digital and conventional impression techniques and workflow. Clin Oral Investig. 2013;17(7):1759-1764.

8. Fasbinder DJ, Neiva GF, Dennison JB, et al. Evaluation of zirconia crowns made from conventional and digital impressions [abstract]. J Dent Res. 2012;91(spec iss A). Abstract 644.

9. Wittneben JG, Wright RF, Weber HP, Gallucci GO. A systematic review of the clinical performance of CAD/CAM single-tooth restorations. Int J Prosthodont. 2009;22(5):466-471.

10. Mehl A, Ender A, Mörmann W, Attin T. Accuracy testing of a new intraoral 3D camera. Int J Comput Dent. 2009;12(1):11-28.

11. Birnbaum NS, Aaronson HB. Dental impressions using 3D digital scanners: virtual becomes reality. Compend Contin Educ Dent. 2008;29(8):494-505.

12. Dunne P. Digital dentistry and SLA technology. Lab Management Today. 2008;Nov/Dec:44-45.

13. Touchstone A, Nieting T, Ulmer N. Digital transition: the collaboration between dentists and laboratory technicians on CAD/CAM restorations. J Am Dent Assoc. 2010;141(suppl 2):15S-19S.

14. Tinschert J, Natt G, Hassenpflug S, Spiekermann H. Status of current CAD/CAM technology in dental medicine. Int J Comput Dent. 2004;7(1):25-45.

15. Pieper R. Digital impressions—easier than ever. Int J Comput Dent. 2009;12(1):47-52.

16. Henkel GL. A comparison of fixed prostheses generated from conventional vs digitally scanned dental impressions. Compend Contin Educ Dent. 2007;28(8):422-431.

17. Alhouri N, McCord JF, Smith PW. The quality of dental casts used in crown and bridgework. Br Dent J. 2004;197(5):261-264.

18. Ender A, Mehl A. Full arch scans: conventional versus digital impressions—an in-vitro study. Int J Comput Dent. 2011;l4(1):11-21.

19. Poticny DJ, Fasbinder DJ. Accuracy of digital model articulation for chairside CAD/CAM restorations [abstract]. J Dent Res. 2012;91(spec iss A). Abstract 705.

20. Givan DA, Burgess JO, O’Neal SJ, Aponte AA. Prospective evaluation of ceramic crowns by digital and conventional impressions [abstract]. J Dent Res. 2011;90(spec iss A). Abstract 380.

21. Nakamura T, Dei N, Kojima T, Wakabayashi K. Marginal and internal fit of Cerec 3 CAD/CAM all-ceramic crowns. Int J Prosthodont. 2003;16(3):244-248.

22. Martin N, Jedynakiewicz NM. Clinical performance of CEREC ceramic inlays: a systematic review. Dent Mater. 1999;15(1):54-61.

23. Otto T, De Nisco S. Computer-aided direct ceramic restorations: a 10-year prospective clinical study of Cerec CAD/CAM inlays and onlays. Int J Prosthodont. 2002;15(2):122-128.

24. Posselt A, Kerschbaum T. Longevity of 2328 chairside Cerec inlays and onlays. Int J Comput Dent. 2003;6(3):231-248.

25. van der Meer WJ, Andriessen FS, Wismeijer D, Ren Y. Application of intra-oral dental scanners in the digital workflow of implantology. PLoS One. 2012;7(8):e43312.

26. Giordano R. Materials for chairside CAD/CAM-produced restorations. J Am Dent Assoc. 2006;137(suppl):14S-21S.

27. Miyazaki T, Hotta Y, Kunii J, et al. A review of dental CAD/CAM: current status and future perspectives from 20 years of experience. Dent Mater J. 2009;28(1):44-56.